yose

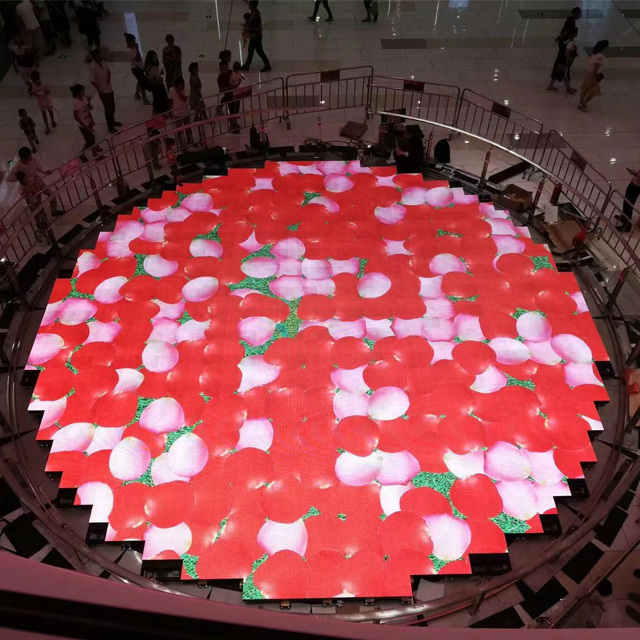

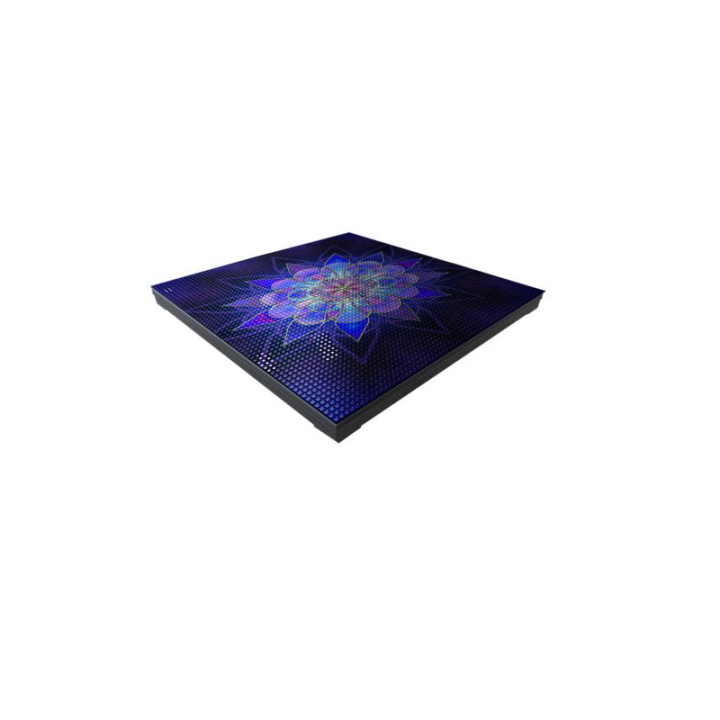

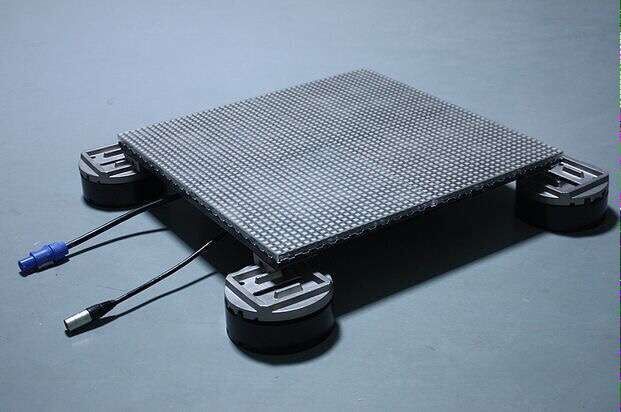

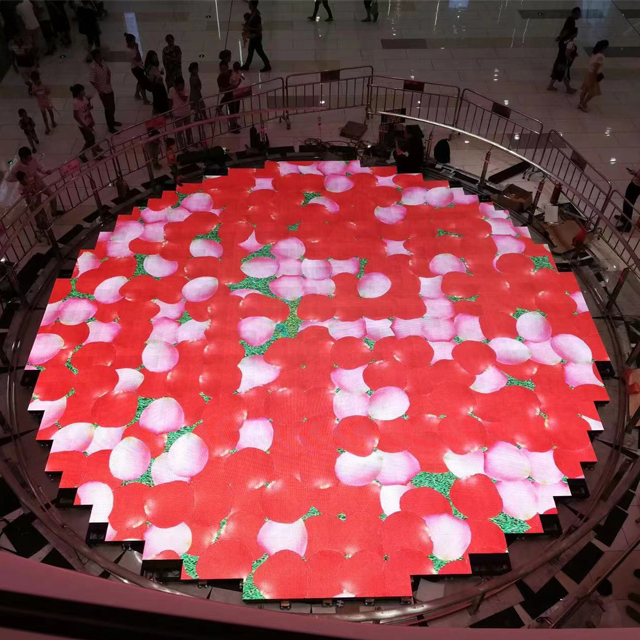

Floor Tile LED Screen

P3.91 led tile screen adopts high-precision seamless splicing technology, which is the most high-definition indoor LED tile screen at present. It has super protective performance, high-definition fidelity effect display (no PC mask, no acrylic board, no glass cover), super wide display angle, waterproof and dustproof, (front IP67, rear IP65) installation height adopts ground pull adjustable scheme, which is suitable for a variety of installation environments.

The surface is packaged by special technology, with anti-collision, anti-collision, anti-static, anti-oxidation, anti UV and other characteristics, in the display effect with no particles, no moire and other excellent display effect

How to interact:

The principle of interactive LED floor tile screen is to add inductive interaction function on the basis of LED floor tile screen. There are pressure sensors, capacitive sensors or infrared sensors in the LED floor tile display screen. When a person moves on the floor tile screen, the sensor can sense the position of the person and feed back the trigger information to the main controller, and then the main controller outputs the corresponding display effect after logic judgment. For example, with the help of infrared sensor, we can track the trajectory of people's movement, follow the human body's activities and present real-time picture effects, so as to achieve such effects as the actor and the audience walk by, water ripples appear at the foot, flowers bloom and so on.

Is the use of PC mask, optimize the previous mask is not anti-skid scratch, increase put vertigo, grain, frosting, and mask cover the whole module, waterproof effect is enhanced, conventional screen all glue, plus the upper cover module outer ring with waterproof rubber ring. The connection between the module and the box body is provided with waterproof rubber ring and screws to achieve a perfect fit.

Box seal:

The box is made of iron plate. Now it is most appropriate to use iron plate for the trampling effect and waterproof effect of the floor tile screen. At present, the shelf life of the aluminum plate box is not long, it is easy to deform, and it is troublesome for later maintenance. Relatively speaking, the shelf life of the iron plate box we make now is longer, because the structure of the box is different from that of the aluminum plate box, and aluminum is added at the back of the box The inner layer of the cover and the aluminum cover is provided with a waterproof rubber ring to realize the sealing between the module and the box, so as to achieve the best waterproof effect.

About heat dissipation:

Just now, it was said that the whole box has been completely sealed, so how to heat? The back cover of the box is specially set as aluminum plate. The back cover is for heat dissipation, and the normal outdoor structure, ventilation and drainage, and heating are not enough to worry about. Normal indoor heat dissipation is not to worry about.

1. Place the floor brackets on the relatively flat ground as shown in the figure (the spacing between adjacent floor brackets is 500mm / 1000mm).

2. Connect the positioning hole at the bottom of the box with the positioning column on the surface of the floor bracket; connect and fix the positioning hole of the box with the four floor brackets in turn (the direction of the arrow on the back of the box must be consistent).

3. Connect the power line and signal line on the back of the box with another box in turn (Note: the direction of the box is consistent).

4. The boxes are connected in sequence according to the above contents, as shown in the figure.

1. The depth of outdoor foundation pit should be between 50-80cm, and the drainage outlet should be reserved, as shown in the figure.

2. Build 30cm-65cm steel structure in the foundation pit (Note: 13cm-17cm height should be reserved between the steel structure support surface and the ground; the distance between adjacent steel structures is 500mm / 1000mm)

3. Place the floor bracket on the surface of the steel structure, as shown in the figure (the spacing between adjacent floor brackets is 500mm / 1000mm)

4. Connect the positioning hole at the bottom of the box with the positioning column on the surface of the floor bracket; connect the positioning hole of the box with the four floor brackets in turn (the arrow direction on the back of the box must be consistent) and adjust the height of the floor bracket to make the surface of the screen level with the height of the ground, as shown in the figure.

5. Connect the power line and signal line on the back of the box with another box in turn (Note: the direction of the box is the same).

6. The boxes are connected in sequence according to the above contents, as shown in the figure.

5. After the installation of the screen, it can be decided whether to install the edge wrapping according to the actual needs to enhance the aesthetics.

6. Regular maintenance is required during the use of the screen to ensure the use time of the screen.

FLKF

FLKF